In the thriving industry landscape in Lahore, Pakistan, the need for durable and effective solutions is constantly growing. One solution that has gained a lot of attention is the zinc coating. This layer of protection, placed on various surfaces, offers numerous benefits for industries and businesses within the region.

Definition of Zinc Coating

Zinc coating, also referred to as galvanization, is the process of applying a protective layer of zinc on surfaces, mostly metal. The process provides an effective shield against corrosion as well as other environmental influences, increasing the life span of machinery and structures.

Significance of Zinc Coating in Industrial Settings

Industries in Lahore recognize the value of zinc coatings in extending the lifespan of the assets they own. From machinery to structural components, the zinc-coated protective layer is proven to be a value-for-money investment over the long term.

Process of Zinc Coating

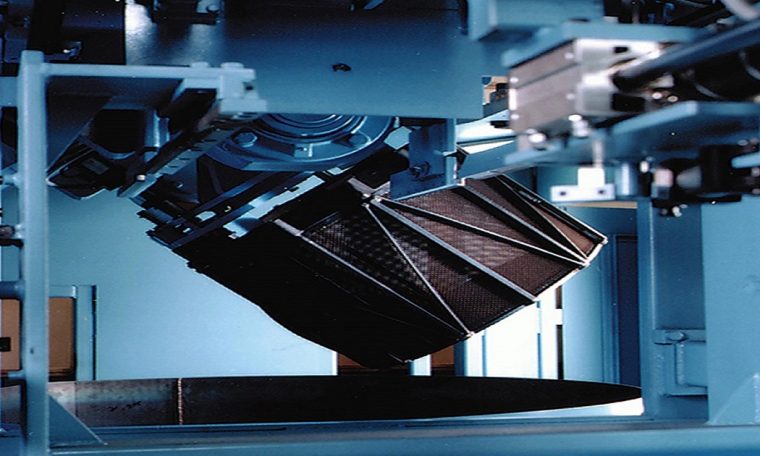

Galvanization Techniques

Galvanization is a broad term that covers a variety of methods, such as electroplating and hot-dip galvanizing. Each method has its uses and benefits, which add to the flexibility that zinc coatings offer.

Types of Zinc Coating Processes

Different industries require different approaches. Knowing the different types of this coating methods ensures that the application is customized to the particular requirements of the coating material.

Benefits of Zinc Coating in Lahore, Pakistan

Corrosion Resistance

Lahore’s industrial center is in the midst of corrosion from the environment. It is an effective barrier, stopping corrosion and maintaining the durability of structures.

Extended Durability in Harsh Environmental Conditions

The climate of Lahore can be extremely demanding. Zinc-coated surfaces are able to withstand the harshest weather conditions, giving you longer durability while reducing the cost of maintenance.

Cost-Effective Maintenance

Investment in this coatings leads to cost savings over the long term. Lower maintenance and replacement costs can make it a financially viable option for companies.

Industries that benefit from Zinc Coating

Construction Sector

It plays a crucial part for the industry of construction, defending the steel structure from corrosion while improving overall structural integrity.

Automotive Industry

Automobiles and other automotive components benefit from the this coating that protects against corrosion, thereby enhancing the durability of the components.

Agriculture and Farming Equipment

In the agriculture sector in which equipment is exposed to harsh conditions, it is essential in maintaining the function of machines.

Environmental Impact of Zinc Coating

Sustainability Aspects

It is known for its environmental sustainability. The process is effective and the product itself is recyclable and aligns with current environmental standards.

Recycling Efforts and Zinc

Recycling efforts in zinc can help to sustain sustainable practices. Reusing zinc is in line with Lahore’s commitment to sustainability.

Technological Advancements in Zinc Coating

Innovations in the Application Process

Technology advancements are increasing the effectiveness of this coatings. New methods of application have led to improved results and less environmental impact.

Emerging Trends in Zinc Coating Technology

Being aware of new trends will ensure that the industries of Lahore remain at the forefront of technological advancements, and maximize the advantages from zinc coated.

Future Prospects of Zinc Coating in Lahore, Pakistan

Anticipated Growth in Usage

These coatings is anticipated to grow due to its established advantages and the continuous expansion of the industries in Lahore.

Potential Applications in Various Industries

As technology improves and new applications for zinc coatings could developed and expand its use to various industries.

Case Studies

Successful Implementations of Zinc Coating in Lahore

Real-life examples show the success of companies in Lahore which have embraced this coatings, reaping the benefits of greater durability and less maintenance.

Real-world Examples of Benefits

Looking at the instances where zinc coatings have significantly improved the outcome gives insight into the advantages that it provides.

Challenges and Solutions

Overcoming Obstacles in Zinc Coating Processes

Problems with the process of this coating can overcome through the right strategy and adhering to quality control procedures.

Continuous Improvement Strategies

Continuous improvement means that the coating gets more effective and beneficial over time.

Comparison with other Coating Methods

Zinc Coating vs. Paint

Comparing it to traditional paint, you can see the superior protection characteristics of the latter in the most demanding conditions.

Zinc Coating vs. Powder Coating

Knowing the difference between powder coating and it can help industries make informed choices in accordance with their requirements.

Regulatory Standards and Compliance

Government Regulations on Zinc Coating

Conformity to the regulations of the government ensures the reliability and quality of zinc coatings in Lahore.

Quality Control Measures

The implementation of rigorous quality control measures will ensure that zinc-coated surfaces conform to the industry standards.

Expert Opinions on Zinc Coating

Interviews with industry experts

Learning from specialists in the field gives you a greater understanding of the specifics of zinc coatings.

Perspectives from professionals In Lahore, Pakistan

Local perspectives provide an overall view of advantages and difficulties associated with zinc coatings in Lahore.

Tips for Choosing Zinc Coating Services

Key Considerations for Businesses

To choose the best coating service requires weighing factors like experience as well as reliability and successful stories.

Selecting the Right Zinc Coating Provider

Selecting a reliable service provider guarantees the efficacy and quality that the coating zinc.

DIY Zinc Coating: Is It Feasible?

Pros and Cons of DIY Zinc Coating

Although DIY zinc coating could appear inexpensive, knowing both the benefits and disadvantages is essential to making educated decisions.

Recommendations for Small-scale Applications

Small-scale applications could benefited from DIY zinc coatings with appropriate instructions and attention to the smallest of details.

Conclusion

Recap of Benefits and Applications

It is found in Lahore, Pakistan, presents numerous advantages. From resistance to corrosion to low-cost maintenance and makes it a worthwhile investment for many industries.

Encouragement for Exploring Zinc Coating Options

Businesses encouraged to look into the possibilities of coating with zinc in the long run, taking into account its benefits and positive effects for the viability of their operation.

FAQs

Does zinc coating work for all kinds of metallics?

It is especially effective for metals that are prone to corrosion, like iron and steel.

When should surfaces coated with zinc be checked to ensure maintenance?

Regular inspections suggested, with frequency dependent on the conditions of the environment and use.

Does zinc coating be placed on existing buildings?

Yes, it is able to applied to new as well as existing structures to increase the durability of structures.

Do you think that DIY zinc coating is an ideal option for industrial use?

DIY zinc coating better suited for smaller applications. However, industrial facilities should consider professional assistance.

Do you have any environmental issues associated with the zinc coating?

It is eco-friendly, and there are efforts made to reuse and recycle zinc while minimizing the environmental impact.